AI Driven Automated Video Content Monitoring For Logistics

VisionBot is a Cloud Based AI & Computer Vision Platform that derives analysable objective data regarding objects, people and events from streaming or stored videos. Our target market is logistics enterprises that need custom object and event detection through 24×7 visual monitoring to improve operational efficiency.

VisionBot leverages Neural Networks and Deep learning to achieve accuracy of detection and minimising false positives. We have built this platform based on our team’s deep skill sets and experience in data science, machine learning and cloud services. We remain in a continuous mode of bringing innovative new solutions around Machine Vision that helps improve operational efficiency of Enterprises.

VisionBot can also be offered as an on premise service in Hybrid / Private Cloud / Data Centre for enterprise requirements. It features an adaptive platform and learns on its own training. Users can also expedite training by providing preferences that makes it more efficient. VisionBot works in both online (real time camera feed) or offline(stored video) modes. It offers the following features:

- Incidents /events report

- Real time event logs

- Alerts for pre-determined events

- Predictive analytics

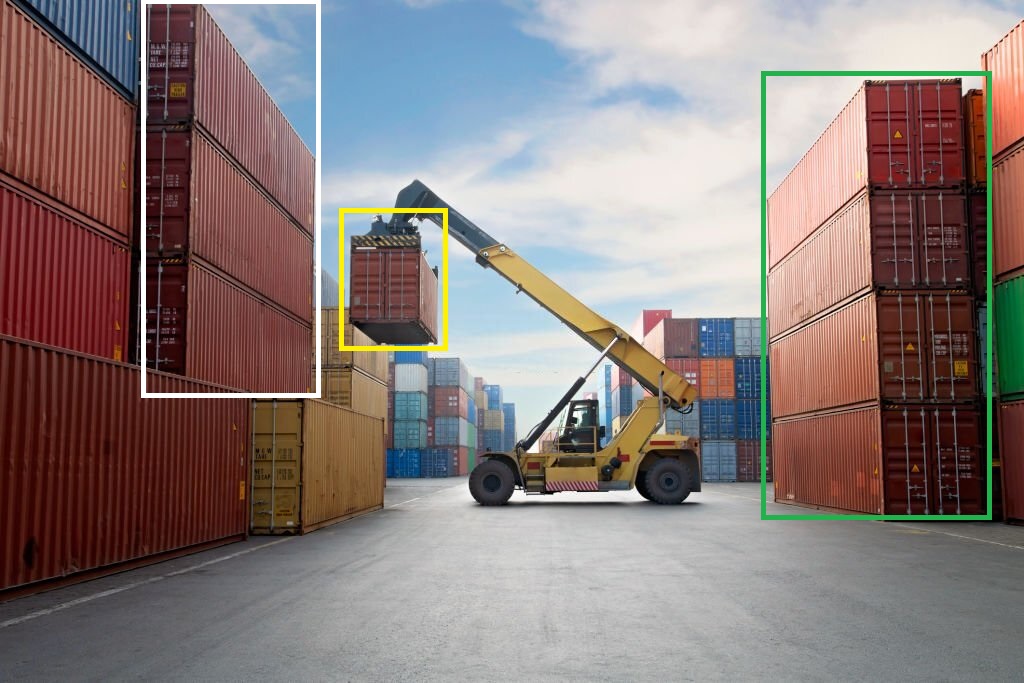

Counting Of Containers / Manifests / Packages

Compliance To Max Tilt Angle Of Containers

IMPLEMENTATION

On Premise Edge Computing

We recommend the On Premise Data Center mode for installations that have or likely to add a large number of cameras. Cameras are easily installed either through our partners or by third party service providers. VisionBot works with most modern IP CCTV camera systems subject to adequate ambient light conditions.

VisionBot server(s) will be installed at local Data Center over a network either cabled or over wide area wifi.

Cloud Based Implementation

For smaller sites or temporary sites we recommend an asset light implementation of VisionBot.

In this case there is no need of installing servers and data centre operations. Cameras can be directly interfaced to VisionBot cloud servers through appropriate internet routers. There is no upfront investments except cameras and switches. This configuration is highly popular and effective as it can also connect multiple sites that provides senior executive 24X7 access to field data and visuals.