Construction company : Inventory Control

Problem Statement:

Pipes of various types are transported from open warehouses to construction sites. Manually counting pipes of different types is difficult on a end of day run – human fatigue leads to erroneous reporting.

Solution:

VisionBot was utilised to leverage camera feeds to detect different types of pipes and count these and thereby keep a daily inventory reconciliation between warehouses and construction sites. This helped the company to seamlessly connect daily physical inventory checks to their ERP system making the workflow efficient and error free.

Manufacturing company: Workplace compliance

Problem Statement:

Regulatory and safety norms require workers to wear proper helmets and footwear and any negligence is to be minimised. Also corridors within factory premises should not be blocked at any point of time. There are penalties in case of violations.

Solution:

Existing camera systems were used to check compliance of workers wearing helmets and safety boots at entrances and within factory premises. VisionBot had been trained for identifying a person wearing the prescribed helmet and safety boots. Also surveillance cameras feeds were used to detect and report objects blocking pathways. This enabled the company to minimise violations without increasing overheads of human supervision.

Preventive Maintenance: Automated monitoring leads to on Demand inspection

Problem Statement:

The maintenance team of the manufacturer has to send inspectors to all their customer locations in distant factory for maintaining large electrical coolant systems that tend to get corroded over time. High corrosion may lead to leakage that can cause emergency shut down of the factory costing significant losses. But mostly inspectors do not report damage but inspection cost is a high overhead.

Solution:

Camera system was installed with VisonBot providing the back end Analytics monitoring the condition of pipes and equipment. VisionBot model was trained for monitoring the equipment 2X7 and detecting three type of conditions of corrosion that automated the preventive maintenance. This enabled the company to reduce overheads of sending inspectors for regular visits to distant factory locations and improved efficiency to on demand inspection based on reporting of VisionBot.

Clothing Retail Chain: Customer Analytics

Problem Statement:

Physical retail outlets unlike their online counterparts do not receive any objective customer analytics except the POS when a sale is already made. The Sales strategy department of this Retail outlet wanted to get customer demographics to improve sales prediction and store inventory mix.

Solution:

VisionBot automated machine vision capabilities was used to analyse and detect features of the customer at entry points through existing / enhanced camera systems. Adequate privacy protection had been allowed as no face or identity recognition is attempted. Customer demography is also studied in display rack areas. The cloud based capability of VisionBot also helped in senior management “drill into” the analytics for better insights. This helped the Sales strategy team to get objective and authentic information from various stores and build a workflow for real time sales prediction.

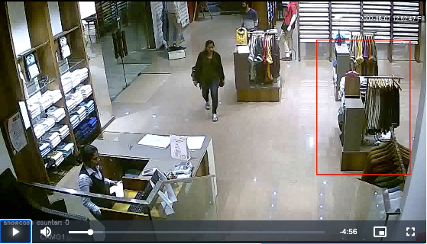

Clothing Retail Chain: Cash Counter Transaction Analytics

Problem Statement:

Cash counters at stores accept payments both by cash or credit cards. Sometimes the payments by cash need to audited on a time of day basis for refunds and best accounting practices. While CCTV recordings are available it is almost humanly impossible to view the entire day’s video footage to find transactions and therefore no attempted.

Solution:

VisionBot custom training capability to detect objects was used in real time feed from cameras at specific intervals. By training the model to distinguish between cash or credit card exchange across the counter it was possible to accurate detect such events and report these in quasi real time. This helped in compliance and implementation of auditing best practices.

Dine in Restaurant Chain: Guest experience Analytics

Problem Statement:

Experience of guests while waiting for entry and in dining areas are important consideration to assess customer satisfaction and suggest improvement. However there is no objective data available except anecdotal information from restaurant staff reports.

Solution:

VisionBot automated monitoring capabilities are utilised to track Guest experience at the restaurant lobby area by analysis of the feed from lobby camera. Feeds from dining area cameras that include tables in their respective fields of view were analysed to detect events as guest vacating tables and clearing of tables that also provided data about the efficiency of the workflow within the restaurant. The cloud based capability of VisionBot is utilised by Sales analysts to centrally access this objective data on dashboard and drill in for details.

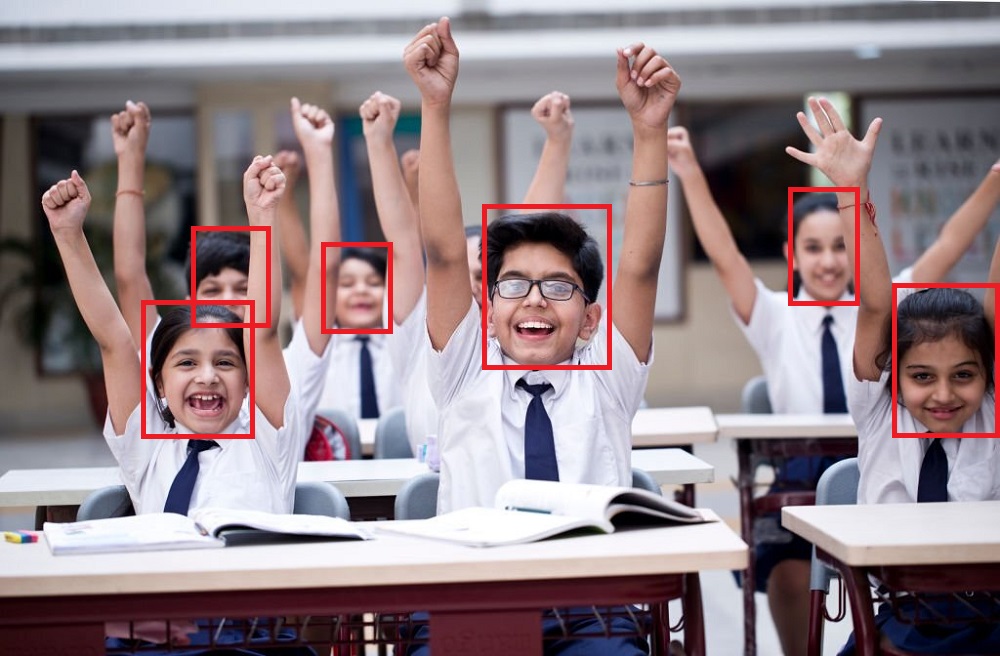

Education institute: Classroom Analytics

Problem Statement:

Attentiveness in classrooms are important and also forms a measure of efficacy of a lecture as much as it is for students. A large private institute having around one hundred centers across the country for K12+ preparatory education planned to include this as a component to score lectures. The classrooms already had cameras as a part of their Smart Class infrastructure. However monitoring hundreds of classrooms manually is a huge overhead on human resources.

Solution:

Automated Computer Vision was utilised to ingest multiple camera feeds from different centers and analyse the collective student behaviour in an objective form (without identification of students and complying to privacy) and providing objective report that was rolled into their existing reporting system.

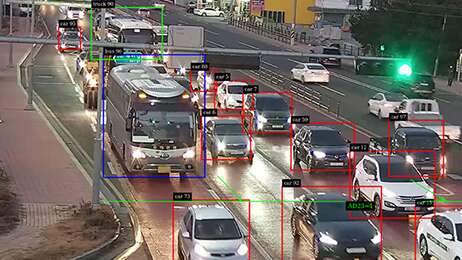

Smart City : Public transport congestion analytics

Problem Statement:

This State road transport system manages thousands of buses plying within the state. In most of the large bus terminals there is a nearby bus depot where buses are stationed before these driven into the terminals for passenger boarding. The coordination of bus depot controller is crucial to maintain punctuality. However there is congestion at terminals during peak hours of the day. The company wanted to analyse terminal congestion based on time of day, daily and seasonal variations. However manually doing this was not considered due to resource constraints.

Solution:

Existing surveillance cameras were utilised to objectively analysed level of congestion at bus terminals round the clock. VisionBot model was trained to identify three types of congestions and this was converted in an on demand reporting system being used at the Bus depot controller for more efficient allocation of buses to the parking bays at the terminal.